Operating a light aircraft is a privilege that few get to experience, offering an unparallelled sense of freedom and a new perspective on our world. However, flying a small piston airplane often involves getting comfortable with technologies that have largely been replaced in modern automobiles. When was the last time you drove a car that used a carburetor, or had to fiddle with a choke or adjust a mixture setting?

Flying any airplane safely requires a deep understanding of how the underlying systems work – especially the engine and its fuel mixture settings. For pilots, having a grasp on how to correctly set the mixture and correctly operate the engine can mean a significant improvement in performance, efficiency, and safety. Your engine is also more likely to reach its TBO if operated according to the aircraft POH.

Key to getting the best out of your piston engine is the correct operation of the mixture. Let’s dive straight in and talk about mixture control; why it's crucial to adjust it correctly for different stages in flight, and how to set it optimally.

Understanding Mixture Control

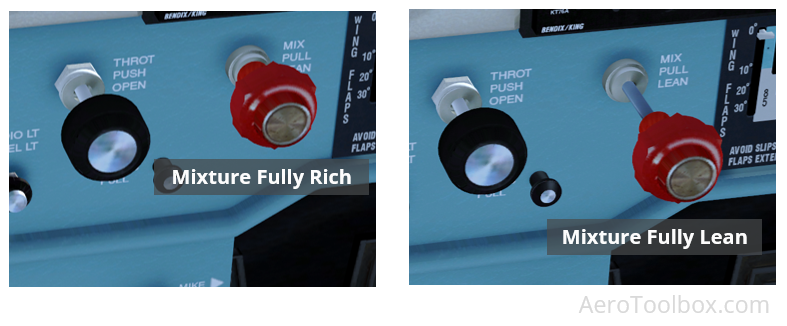

The "mixture" refers to the ratio of fuel-to-air entering the engine’s combustion chamber and is controlled via a lever in the cockpit. Mixture levers are almost always red in color, and usually placed to the right of the throttle lever(s).

Advancing the mixture lever forward allows more fuel to enter the engine, increasing the ratio of fuel-to-air (more fuel per unit of air). This is termed enriching the mixture. Pulling the mixture lever out reduces the amount of fuel entering the engine, reducing the ratio of fuel-to-air, and leaning the mixture.

Pulling the mixture lever all the way out stops the flow of fuel to the engine and shuts the engine down. We call this placing the mixture in idle cut-off.

Why Does Mixture Control Matter?

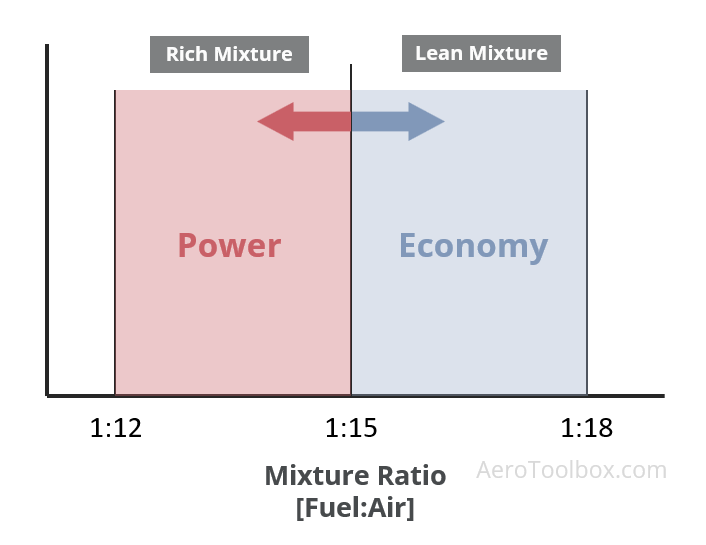

It may seem counterintuitive to some but more fuel entering the engine’s combustion chamber doesn’t necessarily translate to improved performance and increased power. In fact, there is an optimum ratio of fuel-to-air that releases the maximum energy per mass of fuel. This is termed the specific energy of the fuel and will only be reached when there is no unburnt fuel remaining after combustion.

If the mixture is too rich then there is more fuel entering the combustion chamber than can be burnt during the combustion cycle. If the mixture is too lean then there is insufficient fuel entering for an efficient ignition and maximum power.

It is of course vital that the engine is outputting maximum power during the critical stages of flight such as take-off. If the mixture is incorrectly set before take-off then the airplane will not perform as expected with potential disastrous consequences.

Effect of Altitude on Mixture Settings

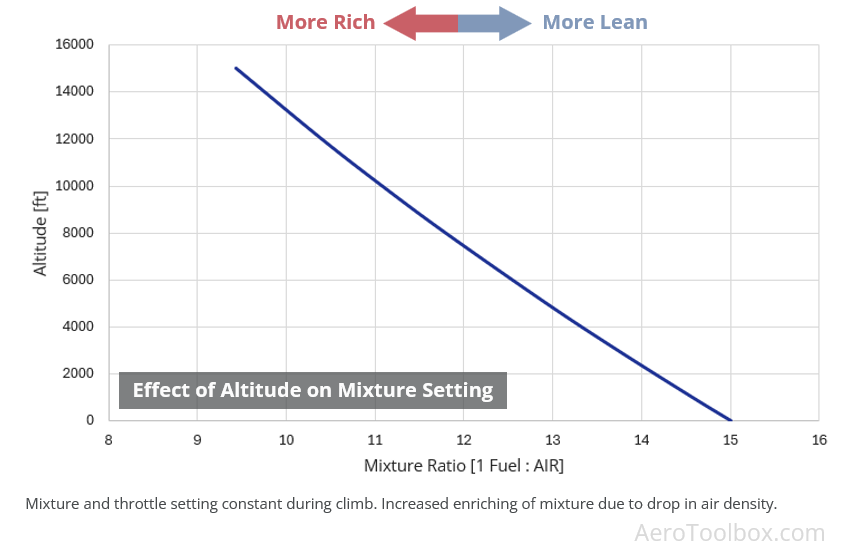

A piston engine will perform optimally at a single ratio of fuel-to-air by mass. The mass of air entering the engine is not constant but is a function of the density of the air. Increasing altitude and higher temperatures both cause the air density to drop.

This means that if you kept the mixture constant as you climbed the ratio of fuel-to-air by mass would steadily increase as the air density dropped. This would result in a continually richer mixture setting, and the engine would cease to operate at its most efficient point.

To compensate for the decreasing air density with increasing altitude you need to progressively lean the mixture as you climb. Similarly, the mixture should be enriched as you descend.

An improper mixture setting can lead to inefficient fuel consumption, reduced engine performance, and even engine damage or failure.

Best Power

The best power mixture setting is the ratio of fuel-to-air that will allow the engine to produce the maximum power. This is the setting that you want during take-off, and usually lies somewhere between 1:11.5 and 1:15 (one part of fuel to fifteen parts air by mass). The mixture control in the cockpit is set up to default to best power when the lever is fully forward. This will give best power when operating at sea level but not when operating from high elevation airfields.

Best Economy

The best economy mixture setting will maximize the power generated by the engine per unit of fuel burnt. This won’t translate to the maximum engine power but will give close to best fuel efficiency which is important in the cruise.

This mixture setting lies somewhere between 1:15 and 1:18, which is a leaner setting.

How to Lean the Mixture Correctly

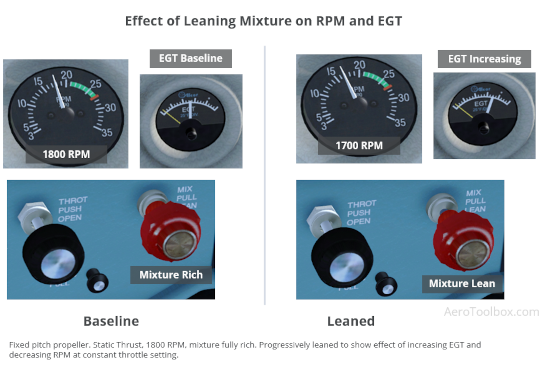

Pilots don’t actually need to know the exact ratio of the fuel-to-air entering the engine to set the mixture correctly. Rather we use the exhaust gas temperature (EGT) as a proxy for the mixture ratio as the EGT changes as mixture changes.

The EGT is directly correlated to the mixture ratio: a richer mixture results in a cooler exhaust gas temperature (at a given power output) as the unburnt fuel aids in cooling the engine. Conversely, a leaner mixture will result in higher exhaust gas temperatures corresponding to a more efficient combustion process.

As the mixture is progressively leaned, the exhaust gas temperature will rise to a maximum before a noticeable drop-off is seen. The peak EGT, which corresponds to the most efficient combustion, always occurs at the same fuel-air ratio but different mixture lever position as the air density varies with altitude and temperature.

The method to set the optimum mixture ratio in cruise differs slightly from aircraft to aircraft but involves progressively leaning the mixture until the EGT peaks, and then either enriching or leaning slightly to reduce the exhaust gas temperature in line with the aircraft flight manual.

Setting the Optimum Mixture of Different Phases of Flight

Here we’ll describe the general procedure to lean the mixture on a single-engine Cessna 172S. This is provided for information purposes only and may differ from the methods described for your aircraft and engine. You should always follow the instructions given in your specific aircraft’s Pilots Operating Handbook.

Ground Operations

For all ground operations the mixture is leaned for maximum RPM and not with respect to the exhaust gas temperature.

Cessna recommend starting the engine and once it is running smoothly, set the throttle to 1200 RPM and then lean progressively until a maximum RPM is reached. You should then set the throttle to an RPM setting appropriate to ground operations, generally between 800 and 1000 RPM.

This leaning procedure is not intended to configure the airplane for takeoff. Generally, when operating below 3000 ft the mixture can be left fully rich.

Take-Off

During take-off, especially at airports that are at or near sea level, the mixture should be set to full rich (maximum fuel). This setting ensures the engine receives the maximum amount of fuel needed for the denser air, providing optimal power for take-off.

When taking off at airports at an elevation greater than 3000 ft you should always lean the mixture before departing to ensure maximum thrust is produced during the take-off roll. The Cessna 172S Pilot’s Operating Handbook recommends that leaning should be done at full throttle in a static runup. Set full power and then progressively lean for maximum RPM.

Climb

As the airplane climbs, it’s essential to gradually lean the mixture. Leaning should be done slowly to prevent the engine from running too hot, which can cause damage. Leaning methods may differ from engine to engine but usually involves finding the best balance between cooling and efficiency.

Cruise

During the cruise phase, the mixture setting should achieve the best possible fuel economy while maintaining adequate power and engine cooling. This is typically done by further leaning the mixture until peak EGT is reached, then enriching slightly until the EGT drops by some predetermined value. Cessna recommends a “rich of peak” setting for cruise where the pilot leans to peak EGT and then enriches the mixture to run at EGT 50°F below peak. Running the engine rich of peak produces near maximum cruise power but at a higher fuel burn as the unburnt fuel is used to cool the engine.

For best economy at higher altitudes the aircraft can often be run at peak EGT. Pay careful attention to the cylinder head temperatures as the engine will be almost entirely air-cooled in this setup as there is no unburnt fuel to aid in cooling.

Finally, it is becoming increasingly popular to run piston engines “lean of peak”. As the name implies this involves leaning to peak EGT before leaning further until the EGT drops by a predetermined amount. Running lean of peak will result in the engine producing less power, with a subsequent drop in cruise performance, but the loss in speed is compensated for by a further improvement in fuel consumption. Depending on the engine setup the engine may also run cooler lean-of-peak, primarily due to the reduction in performance. Essentially the engine is cooled by excess air rather than excess fuel when running lean of peak.

A few important points to note if running lean of peak:

Firstly, lean of peak operations are best left to fuel injected engines rather than carbureted ones as fuel delivery can be more accurately managed. There is often a fairly substantial variation in cylinder head temperatures across a typical air-cooled Lycoming or Continental airplane engine due to the geometry of the engine bay and the relative position of the cylinders. Fuel injectors can be tweaked to provide a consistent mixture (and therefore temperature) across all cylinders.

Second, you need multi-cylinder engine monitoring. If your aircraft has only a single EGT sensor and one cylinder head temperature (CHT) sensor then running lean of peak could potentially damage the engine if one part of the engine is running hotter than is indicated in the cockpit. You may be running lean of peak on one cylinder but at peak CHT on another. Modern sensors allow for accurate CHT and EGT readings across all cylinders which makes it much easier to accurately set the mixture for peak performance.

Descent and Landing

During descent, the mixture should be progressively enrichened to maintain an optimum mixture ratio as the altitude decreases and air density increases. Below 3000 ft the mixture can be placed fully rich to ensure maximum power available in the event of a go-around or any other unexpected situation.

The Importance of Mixture Setting on Takeoff at Higher Elevation Airfields

Operating from airfields located at higher elevations requires special attention to mixture settings. The air at high-elevation airports is less dense than at sea level which means that running the engine at the fully rich setting will result in an overly rich mixture. Not only will this result in a lot of unburnt fuel leaving the engine, but the engine may not be able to produce its maximum thrust which is of course particularly dangerous during take-off. This is particularly pronounced when operating from high elevation airports on a hot and humid day where the density altitude can sometimes be thousands of feet greater than the elevation altitude.

An overly rich mixture can also cause sparkplugs to foul, so it is important to lean the mixture before takeoff such that you achieve maximum thrust. This is usually done by throttling up to a high-power setting and leaning for maximum RPM on a fixed pitch aircraft.

Conclusion

Mastering the art of mixture management is a critical skill for any pilot flying a piston light airplane. By understanding how to set the mixture correctly for each phase of flight, you can improve your aircraft's performance, efficiency, and safety. With some regular practice, and a clear understanding of how leaning or enriching the mixture works, you’ll soon be managing your engine like a seasoned pro, making every flight smoother, more fuel efficient, and most importantly safer.